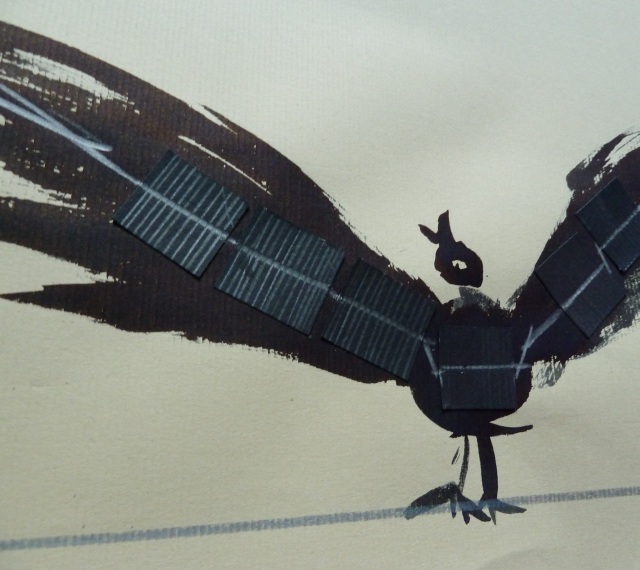

A four-year Functional Electronic Textiles research project funded by the Engineering and Physical Sciences Research Council was successfully completed recently. The project involved creation of a semi-automated production line to embed semi-conductor devices within yarn. As a result, the Advanced Textiles Research Group were able to collaborate with industry and academic partners to make several prototype demonstrators. These are shown in the photos below. The knowledge created was disseminated in refereed journal publications, trade shows and conferences, plus two workshops.

Further details of the Advanced Textiles Research Group’s work via this link: https://www.ntu.ac.uk/research/groups-and-centres/groups/advanced-textiles

A cycling jacket with LED illuminated yarn within the weave

Detail of the inside of a cycling suit covered in electronic yarns containing thermistors to measure the temperature of the skin

A dress illuminated with LEDs included within the Advanced Textiles Research Group’s electronic yarn. The dress was made by Bonnie Binary.

This four year research project was a collaboration between the Advanced Textiles Research Group at Nottingham Trent University and Electronics and Computer Science at the University of Southampton. We acknowledge funding from the Engineering and Physical Sciences Research Council. Project title: Novel manufacturing methods for functional electronic textiles (EP/M015149/1).